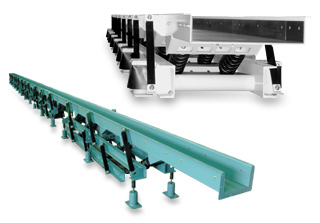

The Electromagnetic Multi-conveyor is a vibration conveyor that uses an electromagnetic drive source.

The resonance model, which uses an electromagnetic drive, is comprised of three elements (trough, frame, and balancer) and enables simple, long-distance operation.

Also, there is no sudden large vibration at startup or stopping and little vibration is transferred to the floor, so the vibration conveyance is environmentally-friendly.

Features

- Long-Distance ConveyanceLengths of 3,4,or 5meters can be combined as desired for long-distance conveyance of up to 30meters.

- Large Reduction in Vibration Transferred to FloorThe vibration transferred to the installation base is extremely small because three elements for resonance are used: the conveying trough, frame, and balancer.

- Easier Maintenance with Simple ConstructionBecause the drive section is electromagnetic, there are no bearings, and so it is not necessary to supply oil.

- High-efficiency, Energy-saving Conveyance with Electromagnetic Resonance DriveThe combination of a high-precision controller, electromagnetic, and drive coil spring enables a mechanism that follows the resonance point.

- Easy to Adjust the Traffic VolumeA newly developed controller enables easy nonstep adjustment of the traffic volume.

- High-precision Stopping PerformanceBecause the system is electromagnetic, the conveyance can stop instantaneously with almost no coasting.

Applications

Conveyance, heating, and cooling of items ranging from micro-powders to large lumps, high-temperature items, castings, foods, etc.

Standard Specifications

| Model number | Controller model number | Processing volume (T/H) | Dimensions (mm) | Weight (kg) | ||

| Trough width | Trough length | Equipment height | ||||

| MCP-30-3L | CMC-15L(H) | 20 | 300 | 3000 | 900 | 500 |

| MCP-60-3L | CMC-15L(H) | 50 | 600 | 3000 | 950 | 740 |

| MCP-90-3L | CMC-22L(H) | 80 | 900 | 3000 | 1050 | 1140 |

| MCP-120-3L | CMC-22L(H) | 110 | 1200 | 3000 | 1050 | 1300 |

| MCP-135-3L | CMC-22L(H) | 125 | 1350 | 3000 | 1050 | 1380 |

| MCP-30-4L | CMC-15L(H) | 20 | 300 | 4000 | 900 | 630 |

| MCP-60-4L | CMC-15L(H) | 50 | 600 | 4000 | 950 | 900 |

| MCP-90-4L | CMC-22L(H) | 80 | 900 | 4000 | 1050 | 1420 |

| MCP-105-4L | CMC-22L(H) | 95 | 1050 | 4000 | 1050 | 2020 |

| MCP-30-5L | CMC-15L(H) | 20 | 300 | 5000 | 950 | 850 |

| MCP-60-5L | CMC-22L(H) | 50 | 600 | 5000 | 950 | 1160 |

| MCP-75-5L | CMC-22L(H) | 65 | 750 | 5000 | 950 | 1270 |

※ The processing volume is calculated with the bulk density of the sand as 1.6.